FLAT-PACK BUILDINGS

FLAT-PACK UNITS

FLEXIBILITY:

A panelized modular unit that offers the flexibility to combine units to create an expandable space. Flat-pack units can be adjoined to create a lager footprint (or) stackable upon themselves.

LOGISTICS:

These units are shipped in a knock-down state allowing for 4-6 units to fit inside a single 40HQ sea freight container, resulting in an unparalleled logistical and freight advantage.

DESIGN:

14 interchangeable SIP (structurally-insulated) wall panels. Move windows and man door locations around as desired. Wall panels are spray-foam insulated, resistance to rot and mould, unlike traditional timber-framed office trailers. Glass Curtain Wall Systems can easily be incorporated for a modern design effect.

PORTABILITY:

Structurally equivalent to an ISO container – units can be lifted by crane, or offloaded by zoom boom or forklift. (dry weight ~5,000 lb each)

STACKABLE:

Units are stackable, engineered to be self-supporting up to 3 units high for living and use.

ASSEMBLY

Units are designed to be user-friendly. Approximately 8mhrs of assembly time requiring only hand-tools and some overhead lift support.

MODULARITY

Flatpacks exhibit tremendous modularity. A truly vertical solution for your temporary job site facilities! Adjoin units together to create a larger complex. Also, the unique ability to assemble-in-place for difficult to access locations such as underground parkades, underground mines etc. These units are the definition of modular!

BUILT FOR CANADA:

Floor and roof structure is insulated to R25 value, SIP wall panels R20, designed to keep you warm in Canada's cold.

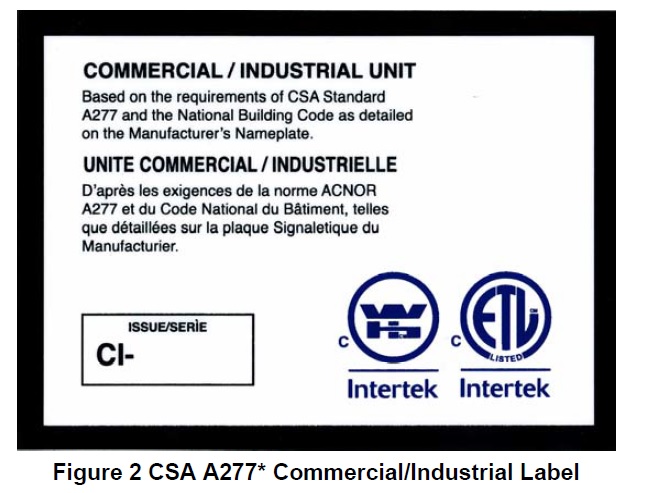

CERTIFIED

Our flat-pack units are CSA A277 certified, Alberta Part 10 compliant. All welding is CWB certified. Units come equipped with CSA/ULC electrical components.

APPLICATIONS

Modular classrooms, site office complexes, security shacks, workforce camps, disaster relief housing, emergency response and refugee housing solutions, underground mining complexes.